I want to talk about micro production.

For background, consumer products over the last 6 decades have largely been built on mass scale, producing as much of it as possible on a mass scale, which drives economies of scale down and drives costs down to serve mass markets. That has worked up until the last decade or so.

Things have started to change where you’ve got more niche markets of customers looking for products that fit their particular needs. So that’s really opening up and requiring the need for smaller production lines to serve those niche markets that are also closer to the customer, as opposed to producing halfway around the world and then shipping something.

That is bringing forth the ability to do micro production, which is largely what I’m trying to do with my pet businesses…very small scale production serving local niche markets.

And I’m really trying to dive into as many of the specifics of production to essentially achieve that. For example, I have traditionally purchased my product labels for my products from a printer, and I last purchased a decent amount several years ago at $.93 cents per label.

But as I have used up that batch of labels, I have figured out that is is cheaper to print in house on our own inkjet printer.

And I can do that for $.53 a label.

I’ve had my graphics artist create elements of the label for me and allow me to then modify myself so that I can do a small print run and make changes to labels without incurring waste.

That is an example of my micro production where in my labels I’ve been able to drive costs down due to technology and do it in house.

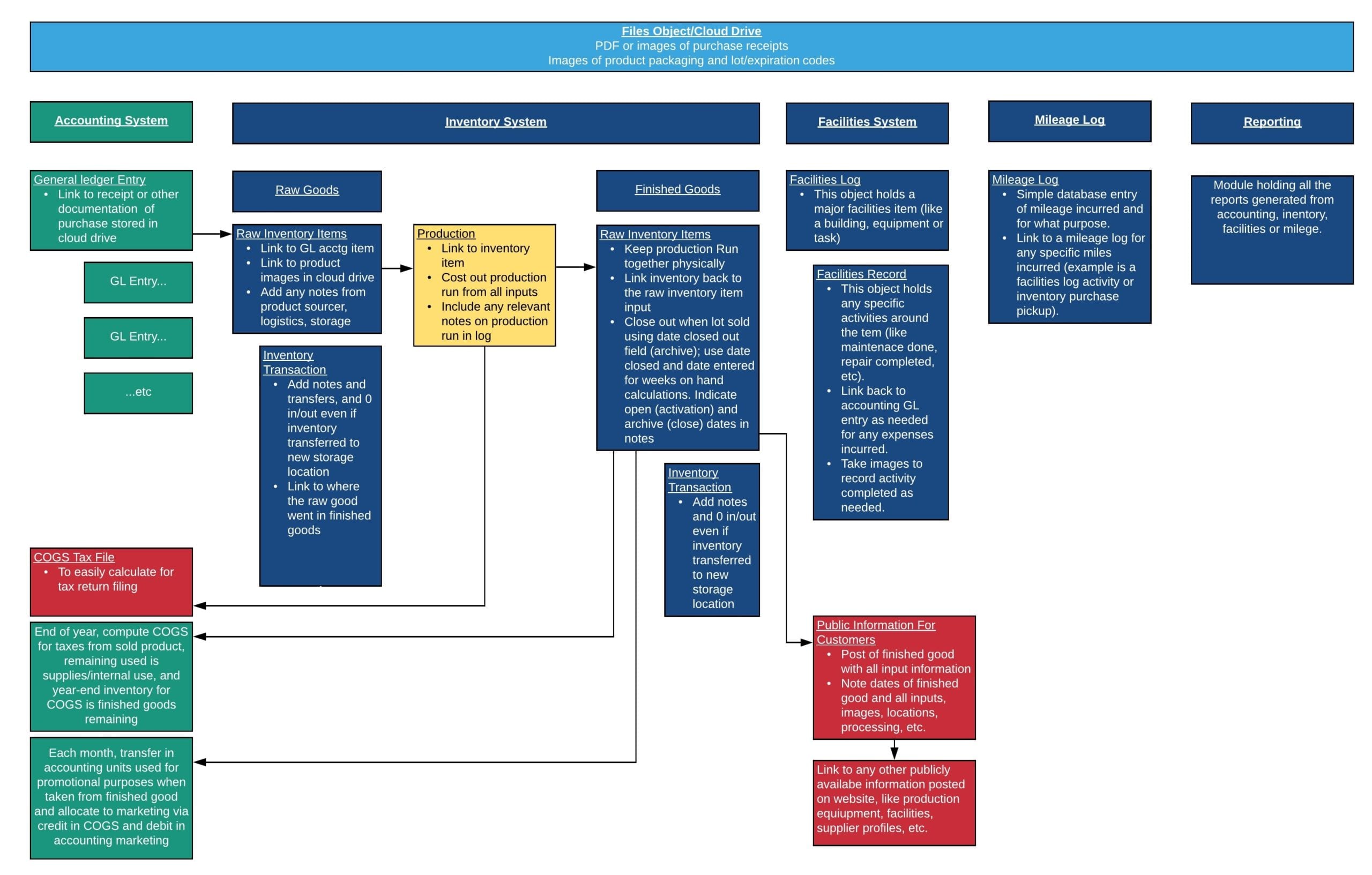

Profitability on mass manufacturing is driven by economies of scale, where you need to produce a lot to earn net margin. But with micro-production, it is really important to drive profitability on small runs. My requirement is to have a net profit margin of 30% on my products that I sell. So it’s really important for me to understand my costs throughout that entire production process to drive the net profit margin I want.

I track all my production runs on a production log where I capture all product details and costs. To see how I do that and download my model, see this post: https://eddiesoehnel.com/ProductProductionLog